M Series Circular Connectors

Electrical Circular Connectors

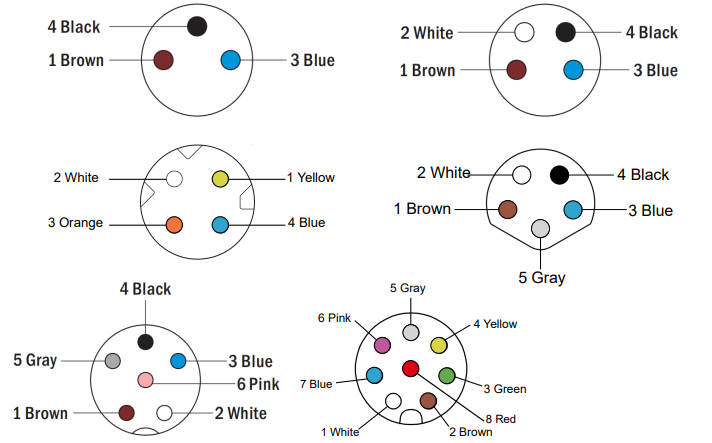

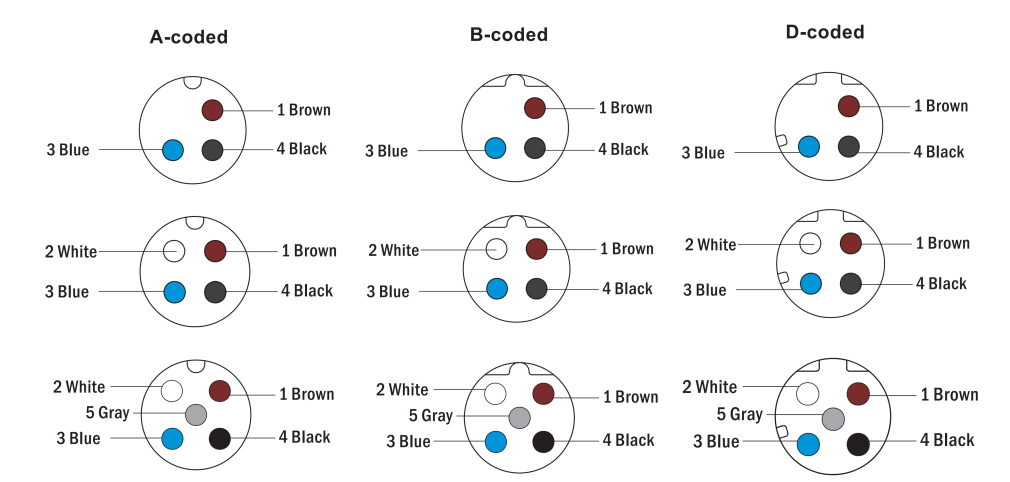

M5/M8/M12/M16/M20/7/8”/M23 serving as different application and requirement

M12 connectors, M8 connectors, M5 connectors, push-pull self-locking connectors, plug and pull connectors, threaded connectors, etc., these connectors have different names because of different electrical performance parameters, but no matter what kind of connectors, they can be widely used in aerospace, automotive, electric power, machinery, automation and electrical services and other industries.

The design of M series connectors is highly scientific and complex, and its design requirements must meet international quality standards to ensure product quality. Connector customization is also a time-consuming and laborious work, according to the special requirements of customers, connector design, material, shape and other details are required to be perfect, in order to meet customer requirements. M12 M8 M5 threaded connectors are also a commonly used connector, they have high tensile strength, strong carrying capacity, reliable fastening and other characteristics, used in automotive, electronics, machinery and other industries, can meet the requirements of different occasions, is an irreplaceable accessory. In addition, waterproof connectors are also a commonly used connector, they usually use multi-layer sealing technology, can effectively prevent water vapor and oil vapor infiltration, very safe and reliable when used in humid environments, is an indispensable part of modern industry.

M series is designed typically for industrial process measurement and control according to IEC standard, offering secure and reliable data as well as superior power transmission performance. Besides the industrial applications, M series is also an ideal solution for a compact design where the environmental protection and stable connection are required.

Shenzhen Yilink provides a comprehensive product range of M series, including M5 / M8 / M12 / 7/8″ and M23, available in receptacle, overmolded cable, field installable and accessory.

M8 PCB connectors are front and rear bulkhead mounted M8 connectors designed for easy handling on the PCB and compatibility with wave soldering processes. M8 PCB connectors include an incorporated wire clip with an integrated PCB retention feature to secure it in the PCB during the reflow process, individual wires come stripped and pre-tinned ready for soldering.

Application:

Electronics, Automotive, Transportation, Medical, Oil Exploration,Industry,Aviation, Metro Device, Bank Device, Network Project

Metal locking ring; screw locking according to DIN EN 60130-9 / IEC 60130-9

• Internal strain relief

• Good shielding effectiveness when mated and locked

• Male and female cable connectors

- Straight or right angled

- Solder connection: 2 – 8, 12 and 14 contacts

- Crimp connection: 2 – 8 contacts

- With cable sleeve for max. cable diameter 6 mm, or

- With cable glands for cable diameter 4 – 6 mm or 6 – 8 mm

• Male and female receptacles

- Panel mount types for front or rear panel mounting

- Pcb mount types, straight or right angled

- With dip solder contacts of various contact lengths

- Solder connection: 2 – 8, 12 and 14 contacts

- Crimp connection: 2 – 8 contacts

• Coloured back shells optional Compatible with Binder original connector

Equivalent connectors Multiple contacts with solder and PCB type

M16 series

High quality compatible circular connectors with Binders 680 518 678 series

Lower cost

Light weight

Screw termination M16 with shielding function

Solder and PCB type contacts are available

Application:

Automotive, Audio-video, Aviation, Communications, Industrial Control, Information Systems, and Machines, Medical, Military, Test and Measurement, Data Acquisition, Data Transfer Equipment. Module Power, Sensor, Sensor Systems Instrumentation, Analysis Application.

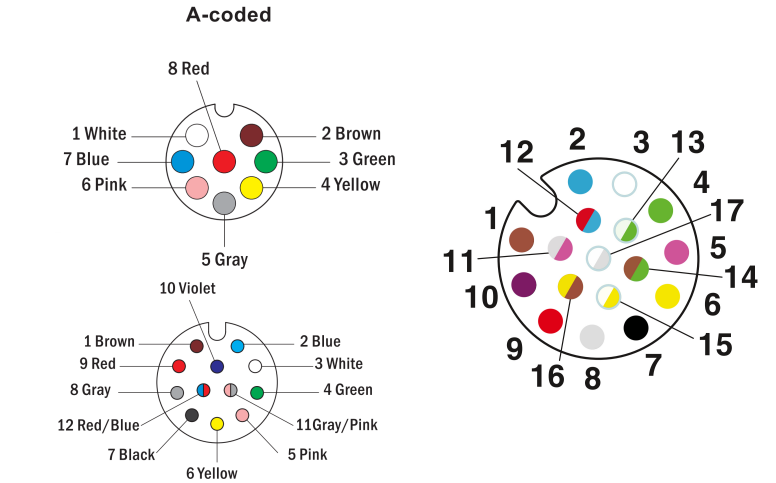

M23 for Power Series with multi-core(6-19 core) design to fit with different industrial needs within below key features:

1:The shell is made of Brass with chrome plating and has good fireproof, compressive, anti-explosive and anti-deformation

properties.

2:Gold-plated contacts, high-strength corrosion resistance and electrical conductivity, can electively cope with changes in

temperature rise that caused by current;

3:Threaded coupling is easy to operate and easy to install;

4:Current rating:8A/10A/20A/28A

5: The product is IP67 rated in the connected condition.

Usage and installation methods

Plug-ins are also called electric connectors. They are known as industrial connectors and socketsand often used unshielded multi-core

cables and can play a role in transmitting current or signals, fix cable tampering, shielded grounding, and waterproof dust protection.Yilink

has developed a high-load plug-in connector, which can be installed quickly. The installation seat(socket) can be fixed by M3 screws, M25/M20 and

other specifications such as box thread holes, and various specifications box holes. The connection between the cable connection plug(plug) and the

installation seat(socket) is only required to be tightened and fixed by the self-tightening nut,and the installation is flexible and convenient.

Application:

The products of Yilink refer to rail transit, new energy vehicles, industrial automation, energy, photovoltaics, stage lighting, exhibitions,medical, agriculture and other fields.

Connector Body: PA66+GF

Contacts: Phosphorus copper with gold plated

Screw/Nut: Brass with nickel plated

Waterproof 0-ring: FKM

Glue: Black epoxy resin

Wire Jacket: PVC

Contact Resistance: ≤10mΩ

Insulation Resistance: ≥100MΩ

Application:

This series connectors are widely used in the aerospace, military, automotive, electric power, mechanical, automation, as well as the electrical service industry. We design and produce according to international and the U.S. military standard, our products can substitute European, US and Taiwan connectors, own the same quality.